Backflow Control and Prevention

Microbiologically Influenced Corrosion in Fire Sprinkler Systems

What is Microbiologically Influenced Corrosion (MIC)?

Microbiologically Influenced Corrosion (MIC) is a type of corrosion which is initiated by microbiological life forms and occurs often in fire sprinkler systems. Certain species of bacterium aid in the corrosion cell creation and propagation of the corrosion process. There are three main groups of bacteria which are responsible for MIC, each group is named after its specific function on metallic surfaces:

1. Acid Producing Bacteria (APB): This group is comprised of bacteria which actually create organic and inorganic acids (acetic acid, hydrochloric acid, sulfuric acid, etc.) as a waste product in their function. The created acid is very corrosive to metallic surfaces. They are mainly anaerobic (do not need oxygen to function). They are responsible for localized corrosion and pit formation.

2. Sulfur Reducing Bacteria (SRB): This group is comprised of bacteria which reduce available sulfur and react with iron on metallic surfaces to form iron sulfide and hydrogen sulfide gas, as waste products. The hydrogen sulfide gas forms sulfuric acid when exposed to water and the acid's actions create pitting in the metallic surface. SRB can actually use the hydrogen on the metals surface as an electron donor and

derive their energy in the reduction of sulfur. They are mainly anaerobic (do not need oxygen to function).

3. Iron Related Bacteria (IRB): This group of bacteria is comprised of bacteria which derive their energy from either oxidizing or reducing iron. They are primary in the building of corrosion tubercles and their corrosion process is more general on metallic surfaces.

Why has Microbiologically Influenced Corrosion (MIC) become a problem in fire sprinkler systems?

Why has Microbiologically Influenced Corrosion (MIC) become a problem in fire sprinkler systems?

Corrosion has always been a problem in fire sprinkler systems but it was incorrectly identified and misunderstood. With the development of thin-walled piping in recent years, the issue has come to the forefront as the time for corrosion to become apparent in the form of pin-holes has decreased. Wet, dry and pre-action systems have seen a notable increase in corrosion since the 1990's. Monitoring and mitigation is needed to forecast and diminish the harmful and costly effects of MIC. Testing of water, sludge and tubercles form the interior of the piping is required to fulfill certain areas of NFPA and NFPA 25.

Pinholes, black water, smelly water and tubercles are NOT normal and, if present, indicate the need for testing and control!

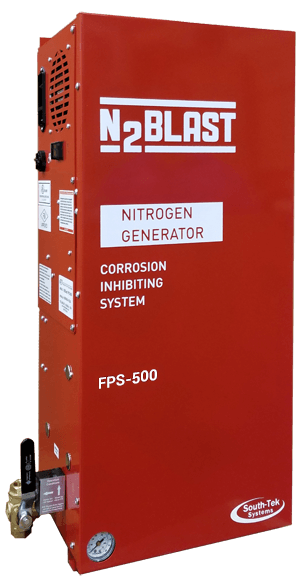

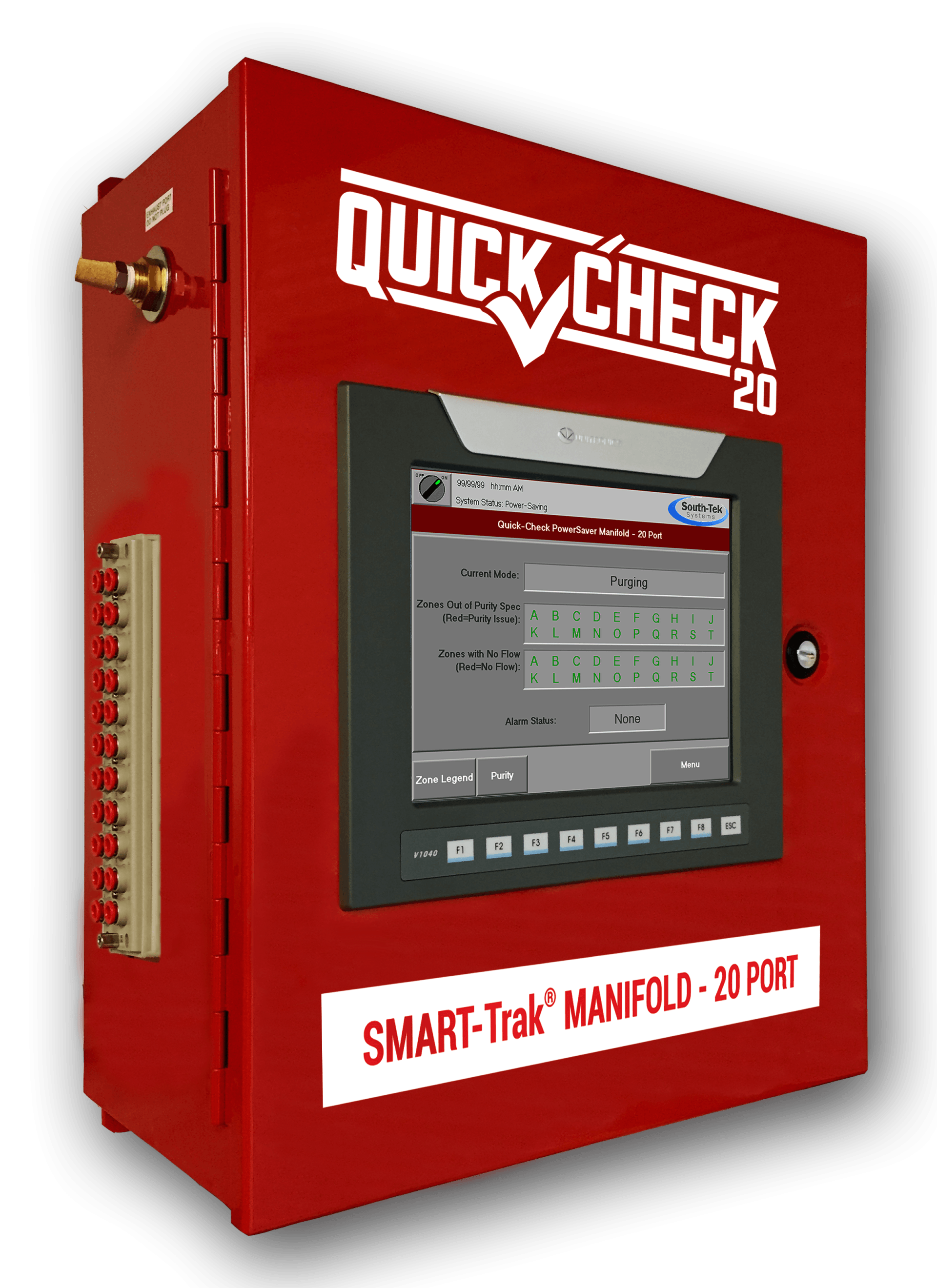

Advanced Fire Protection was the first in New England to install and maintain a MIC Control / Monitoring Station, manufactured by South-Tek Systems. We inspect and test fire sprinkler systems regularly for the onset of microbial corrosion. It is very important to the integrity and fire-fighting readiness of your fire sprinkler system to conduct this testing on a regular basis.

Call us to discuss MIC and find out if you should be concerned about your fire sprinkler piping. If no preventive measures are indicated, we'll be the first to tell you!

A MIC CONTROL / MONITORING SYSTEM MAY INCLUDE SEVERAL SPECIALIZED DEVICES